polycarbonate impact testing|polycarbonate strain rate : online sales Fracture energies in polycarbonate and PMMA were measured using different test techniques. Results from instrumented impact tests and slow three-point bend tests on Charpy specimens were compared with tensile test results on Compact Tension (CT) specimens. . Charpy test at a low rate, do G~c values for both PMMA and PC become close to the CT .

Treated Freshwater Cultured Pearl Hoop Earrings. $150.00. .

{plog:ftitle_list}

WEBJogo 1win Brasil Aviator. O jogo Aviator é popular em todo o Brasil e mais conhecido como um jogo de avião pequeno. Ele agora está disponível no site 1win. O jogo foi desenvolvido pela Spribe, uma grande .

how polycarbonate should and should not be used. Notched Izod impact testing is an experimental method to quantify the energy absorbed by the polymer during the adverse loading conditions of high triaxiality and high rate. Extensive Izod testing of polycarbonate has been . In this paper, Taylor impact experiments were conducted to examine the mechanical behavior of polycarbonate (PC), under conditions of high strain rate (∼10 5 s −1) and . Therefore, in this work, PD is applied to investigate fracture behavior of other polymer, i.e. polycarbonate (PC) in Charpy impact test. 3.1.2 Charpy Impact Test. One of the standard tests which provide fracture criteria is Charpy impact test. This test is a standardized high strain-rate test that measures the amount of energy absorbed by a .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

The 3.23mm Notched Izod impact test was successfully modeled from initial contact of the pendulum through initiation of failure and early tearing. The yielding patterns and failure occurred along the same lines as in the experiment where diagonal shear bands and lobes initiate plastic deformation from the notch tip and tearing progresses in a .

Fracture energies in polycarbonate and PMMA were measured using different test techniques. Results from instrumented impact tests and slow three-point bend tests on Charpy specimens were compared with tensile test results on Compact Tension (CT) specimens. . Charpy test at a low rate, do G~c values for both PMMA and PC become close to the CT .

While Charpy impact testing is used primarily for metals, the Izod method is commonly used for polymer and plastic impact testing. It helps assess the impact resistance of plastic materials used in consumer products, automotive components, and packaging materials. Izod impact test standards. ASTM D256, ASTM D4508, ASTM D4812

These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure. These test are typically pass/fail tests: They give the average impact energy required to break the samples. The Multiaxial impact test produces a load-deflection curve. Numerous data values related to toughness and total energy . Polycarbonate Testing Standards . Because of its longevity on the market, polycarbonate has been tested thoroughly by government agencies, militaries, industrial users, and manufacturers against several standards. . Depending on the customer’s needs for ballistic impact, we use the 1.25-inch polycarbonate in our ballistic-resistant mobile .

The Charpy and the Izod impact tests have a number of differences in addition to their many similarities. One of these variations is the ability to use either metallic or plastic specimens for the Izod impact test. The standard size of plastic samples is a bar with the following dimensions: 64 mm x 12.7 mm x 3.2 mm (V-shaped).Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

However, these tests generally don't translate into explicit design parameters. The Izod impact test is the most common test in North America. The figure below, from Mitsubishi Chemical Advanced Materials, depicts the Izod impact strength test apparatus. ASTM D256: A pendulum swings on its track and strikes a notched, cantilevered plastic sample.

1.1 This test method covers the determination of the energy required to initiate failure in monolithic polycarbonate sheet material under specified conditions of impact using a free falling weight. 1.2 Two specimen types are defined as follows:Notch test: 20–35 kJ/m 2: . Its low weight and high impact resistance have made polycarbonate the dominant material for automotive headlamp lenses. However, automotive headlamps require outer surface coatings because of its low scratch resistance and susceptibility to ultraviolet degradation (yellowing). The use of polycarbonate in .D4321-24 Standard Test Method for Package Yield of Plastic Film . D2684/D2684M-24 Standard Test Method for Permeability of Thermoplastic Containers to Packaged Reagents or Proprietary Products . D1709-24 Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method . Mechanical Properties

Battery testing enclosure manufactured with polycarbonate panels. Mobile shielding enclosure designed to contain projectiles impact from a pneumatic compressor upon failure. It's capable of withstanding fittings and components of small diameter, made of metal, and offers a pressure release solution through its vented panel on top of the unit. Sorry for the lack of comparison but the weight bounced and knocked my camera down and it didn't save the recording.. I did a simple impact test for a DIY wi.ASTM D4508, an Izod test method for measurement of small specimens (Chip impact), which is a counterpart to the Dynstat impact test to DIN 53435. ISO 180 describes the Izod impact test for determination of the impact and notched .

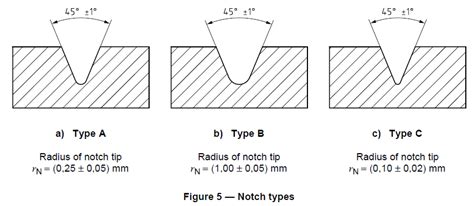

Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm. Data: ASTM impact energy is expressed in J/m or ft-lb/in. Impact strength is calculated by dividing impact energy in J (or ft-lb) by the thickness of the specimen. The test result is typically the average of 5 specimens.Polycarbonate is a versatile plastic. It is widely used in this world. It is commonly known by its abbreviated form – PC. Properties like transparency, impact resistance, and high temperature resistance make it a favorite material. We definitely see its use in many industries. The market size for PC currently in 2024 is valued at [.]

Though all varieties of polycarbonate exhibit exceptional tensile strength, the actual numbers vary somewhat from product to product. SL. Our clear SL polycarbonate sheets provide the transparency of glass in concert with superior impact resistance and tensile strength. Its ultimate tensile strength of 9500 psi and yield tensile strength of .Clear polycarbonate panels with sliding door and vented panels. Dimensions: 6'x7'x7' Standard safety blast-resistant room designed to protect during high-impact scenarios against a dyno testing spinning at high velocities (rpm), with steel panel for cable management and vented panel on the roof for HVAC duct integration.Flexural Test - Composites Four Point Bending ASTM D6272; Flexural Test - Composites ASTM D7264; Flexural Test - Core (4-pt flexure) ASTM D7249; Flexural Test - Facesheet Compressive Strength ASTM D5467; Fogging SAE J1756, ISO 6452, DIN 75201; Fourier Transform Infrared Analysis (FTIR) ASTM E1252; GHI: Gardner Impact ASTM D4226, D5420, D5628 The uniaxial compression mechanical behavior of polycarbonate has been measured at strain rates ranging from 3.8 × 10-5 s-1 to 8200 s-1. The effect of strain rate on the yield stress of .

One of the difficulties in evaluating the impact resistance of polycarbonate (or change in impact resistance) is the lack of a universally accepted and standardized test method. Some transparency vendors rely on the falling weight impact test which yields good qualitative results. However, to date these falling weight impact tests have often beenGE: The test conditions are the same as those in test method ASTM D4226. The impactor head configuration H.25 (0.48 in 6 0.04 in. (1.22 cm 6 0.10 cm)) is employed; The selection of a test method and striker is arbitrary considering the nature of impact testing.

Video: ¼” Polycarbonate Shutter Impact Test (click image to view video) Impact rated residential doors and windows or the protective systems for doors and windows are tested to determine their ability to resist the impact of large wind borne debris (missiles) by shooting 2x4s of specified lengths and weights against them at specific speeds.

hanna instruments hi 903 karl fischer volumetric titrator sourcing

Promocao Sabadao - hobbymotel.com.br

polycarbonate impact testing|polycarbonate strain rate